Calcium fluoride (CaF2) optical windows have become essential components in various optical systems, drawing attention from experts across multiple fields. Their unique properties have made them indispensable in scientific research, industrial applications, and high-precision instruments. In this article, we will explore the applications of calcium fluoride optical windows, including insights from industry professionals to provide a comprehensive understanding of their significance.

**Optical Performance and Durability**

Dr. Emily Huang, a senior optical engineer at a leading materials science laboratory, emphasizes the strength of calcium fluoride in harsh environments. “Calcium fluoride has superior transmission capabilities in the UV to IR range, making it ideal for various applications, from spectroscopy to thermal imaging,” she states. She notes that these windows can withstand exposure to extreme temperatures and harsh chemicals, making them a reliable choice for laboratory setups.

**Applications in Laser Technology**

Another expert, Professor Michael Adams, who specializes in laser optics, points out the relevance of calcium fluoride windows in laser systems. “Many high-power laser applications require materials that can handle significant energies without damaging the optical component,” he mentions. His research shows that calcium fluoride's low absorption coefficients prevent thermal damage, which is crucial for maintaining beam quality in laser applications.

**Use in High-Performance Systems**

Dr. Sarah Mitchell, who has worked extensively in aerospace engineering, shares her thoughts on the importance of calcium fluoride in her field. “In aerospace applications, the optical systems must operate effectively under varying atmospheric conditions. The low refractive index and minimal wavefront distortion of calcium fluoride make it an ideal candidate for windows in satellite and aircraft sensors,” she explains. Her findings highlight how calcium fluoride windows enhance the performance of optical systems in demanding environments.

**Integration with Other Optical Components**

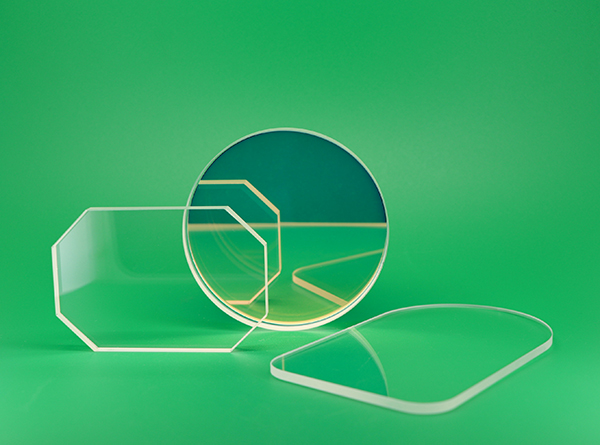

Calcium fluoride optical windows are often integrated with other components such as

spherical lenses and

cylindrical lenses. According to Dr. Alex Rivera, a physicist at a national lab, “The synergy between these components leads to superior overall system performance. By minimizing reflection losses and ensuring high transmission, we achieve remarkable results in imaging and sensing applications.”

**Future Trends and Innovations**

As the demand for advanced optical components grows, industry experts anticipate continued innovations in calcium fluoride technology. Ms. Jessica Lee, a product manager at

CLZ Optical Co., Ltd., notes, “We are constantly improving the manufacturing processes of calcium fluoride windows to enhance their capabilities further. Future applications may encompass new areas such as quantum communication and next-generation imaging systems.”

In conclusion, calcium fluoride optical windows play a pivotal role in enhancing optical performance across various industries. Their unique characteristics, as highlighted by experts, demonstrate their importance in applications that require precision and reliability. For those seeking high-quality

Optical Windows, understanding these insights can significantly impact their selection process.

With their vast applications ranging from spectroscopy to aerospace engineering, calcium fluoride windows are set to remain a cornerstone of modern optical technology. For more specialized needs, such as

optical domes or

filters, it is important to consult with reliable manufacturers to find the best solutions. The advancement in this field promises exciting developments that will shape the future of optics.

Comments

Please Join Us to post.

0